-

tel:

+86-13616182007 -

email:

E-mail:sales@wuxisunway.com

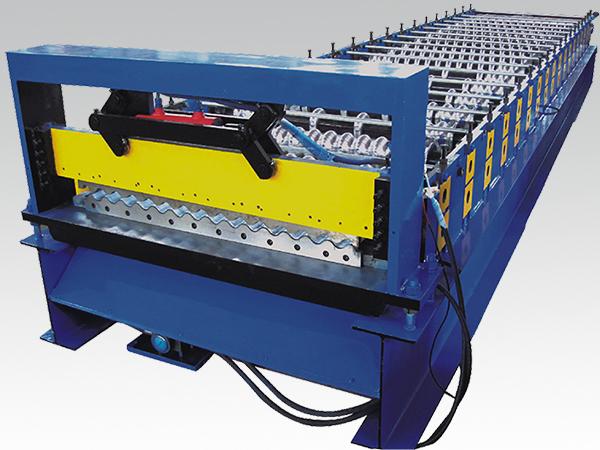

Thin Sheet Slitting Line

This thin sheet slitting line, also called metal coil slitter, is a kind of production line to break down master coils into smaller coils of a particular width. The thin sheet slitting line is made up of coil-loading car

We can also supply the customized machines.

Introduction:

Because thickness of coil strips is in proportion to capacity of sheet slitting lines, the bigger thickness of master coils need the bigger models of coil slitting machines. Generally, we can classify slitting lines into three groups according to thickness difference, that is, thin sheet slitting line, middle thick coil slitting machine and thick coil metal coil slitter.

This thin sheet slitting line, also called metal coil slitter, is a kind of production line to break down master coils into smaller coils of a particular width. The thin sheet slitting line is made up of coil-loading car, single mandrel uncoiling, coil-end-feeding and shoveling, double roller pinching feeding, three-roller-leveling, end-cutting, strip-aligning, disk shearing, scrap reeling, hole accumulator, pre-separator, tensioning, recoiling ,coil down car, hydraulic control, and electric control.

Thin sheet slitting line is suitable for coil strip thickness (0.2~1) mm, (0.3-2) mm, (0.3-3) mm and (0.4-4)mm; while strip width is changeable: 600mm. 1000mm, 1250mm, 1600mm, 1800mm and so on.

Advantages & Characteristics of our Coil Slitting Machine:

1. Each production line (thin sheet slitting line) is designed and made strictly according to customer requirements. Not only this, our engineers carefully think over in customer's shoes, making sure whole metal coil slitter to be compact, smooth, solid and easy to operate.

2.Thin coils differ in coil weight, when max coil weight is small, usually single mandrel (cantilever) uncoiler is adopted for the metal coil slitter; when max coil weight is up to 25Tons, it is proper to use double mandrel uncoiler for the coil slitting machine.

3.Customer usually need narrow thin strips in high slitting precision. We attend much attention to centerline control, slitting accessories precision control, recoiling precision control, etc to make sure slitting precision at thin thickness.

4.When stainless steel, galvanized steel, colored steel coils are concerned, we take delicate measures such as rubber rollers, smooth transmit plates to protect sheet perfect surface not injured.

5.We have obvious advantage in hydraulic system design and production for this the thin sheet slitting line.

6.We always choose good suppliers of hydraulic parts, motors, speed reducers, electric parts. As well, we like to purchase those parts according to customer requirements for special metal coil slitter.

7.We strictly control each link of production process, from material purchase, to welding, machining, hardening & grinding, to assembly, to painting. Therefore, we can make sure good quality metal coil slitter.

8.We can supply same quality coil slitting machine at cheaper prices because we are good at production cost management.

9.AC motor or DC motor drive, customer can freely choose. Usually we adopt DC motor and Eurotherm 590 DC driver due to its advantages of stable running and big torque.

10.Safety operation is ensured by clear indications on thin sheet slitting line, safety devices such as emergency stop, etc.

The detail specification as follows:

1. SW-(0.2~1)×600mm Thin Sheet Slitting Line domestic customer

Material of coils: carbon steel, color steel, galvanized steel and etc

Strip thickness: (0.2~1) mm

Strip width: 600mm

Inner diameter of coils: Φ508mm

Max. Outer diameter of coils: Φ1500mm

Max. Coil weight: 8000kg

Recoiling block: Ф508 x 700

Recoiler motor: AC 37KW Slitter shaft: Ф180 x 700

Slitter motor: AC 22KW

Material of disc cutter: ID180mm x OD300mm x 8/10mm, 6CrW2Si, HRC58-60.

Slitting speed: (0~50) m/min, adjustable

2.SW-(0.3-2)×1300mm Metal Coil Slitter in Venezeula

Material of coils: carbon steel, stainless steel, galvanized plate, colored steel plate

Strip thickness: (0.3-2) mm

Max. Strip width: 1300mm

Inner diameter of coils: ≥Φ508mm

Outer diameter of coils: Φ1800mm

Max. Coil weight: 15000Kg

Slitter motor: 55KW DC motor

Slitter shaft: Ф205 x 1400mm

Disc knives on slitter shaft: ID205mm x OD310mm x 10mm, 6CrW2Si(H13, SKD-11).

Separating disc: ID75 x OD180mm x 6mm, 65Mn

Tensioning provided by strip passing through frictional wool felt wrapping around wooden plates.

Recoiler block: Ф508 x 1400mm

Recoiler motor: 75KW DC motor

Electric control: Eurotherm 590 DC driver cabinet plus control panels.

Slitting speed: max 80m/min, adjustable.

3.SW-(0.3~3)×1600mm Coil Slitting Machine in Serbia

Material of coils: HRC, CRC, GI, PPGI, Q195, Q235, Q345...

Strip thickness: (0.3-3) mm

Max. Strip width: 1600mm

coil ID: ≥Φ508mm

Coil OD: Φ1800mm

Max. Coil weight: 20000Kgs

Slitter motor: 75KW DC motor

Slitter shaft: Ф220 x 1650mm

Disc knives on slitter shaft: ID220mm x OD330mm x 10mm, 6CrW2Si.

Separating disc: ID85 x OD210mm x 6mm, 65Mn

Tensioning provided by strip passing through frictional wool felt wrapping around wooden plates.

Recoiler block: Ф508 x 1700mm

Recoiler motor: 90KW DC motor

Electric control: Eurotherm 590 DC driver cabinet plus control panels.

Slitting speed: max 100m/min, adjustable.

4.SW-(0.4~4)×1600mm Coil Slitting Machine (Slitting Line), domestic

Material of coils: HRC, CRC, GI, PPGI, ST37, ST52.....

Strip thickness: (0.4-4) mm

Max. Strip width: 1600mm

Coil ID: ≥Φ508mm

Coil OD: Φ2000mm

Max. Coil weight: 30000Kgs

Slitter motor: 75KW DC motor

Slitter shaft: Ф220 x 1650mm

Disc knives on slitter shaft: ID220mm x OD330mm x 10mm, 6CrW2Si.

Separating disc: ID85 x OD210mm x 6mm, 65Mn

Tensioning provided by strip passing through frictional wool felt wrapping around wooden plates.

Recoiler block: Ф508 x 1700mm

Recoiler motor: 90KW DC motor

Electric control: Eurotherm 590 DC driver cabinet plus control panels.

Slitting speed: max 80m/min, adjustable.

Specification form of Coil Slitting Machine:

| Model | Thickness | Width | Coil Weight | Finished slit width | Max Slitting speed |

| SW-1 x 600 | 0.2-1mm | 100-600mm | Max 8T | Min. 20mm | 50m/min |

| SW-2 x 1300 | 0.3-2mm | 300-1300mm | Max 15T | Min. 25mm | 80m/min |

| SW-3 x 1600 | 0.3-3mm | 500-1600mm | Max 20T | Min 25mm | 100m/min |

| SW-4 x 1600 | 0.4-4mm | 500-1600mm | Max 30T | Min 30mm | 80m/min |

| Note: The data in the form just as reference according to general ranges, we always design and make each line according to each customer's specific requirements, so each customer can buy his own well-content line from us. | |||||

Wuxi Sunway Machinery Co.Ltd is a professional manufacturer and supplier of thin sheet slitting line, Coil Slitting Machine. For more information about coil slitting machine, please send us inquiry. Thin Sheet Slitting Line Layout Drawing