-

tel:

+86-13616182007 -

email:

E-mail:sales@wuxisunway.com

Steel Truss Roll Forming Machine

Steel Truss Roll Forming Machine Name:Steel Truss Roll Forming Machine Model:YX Series Steel Truss Roll Forming Machine is to produce the self-supported steel deck for steel structural floor decking. We can also supply the customized machines.

We can also supply the customized machines.

Features of Steel Truss Roll Forming Machine

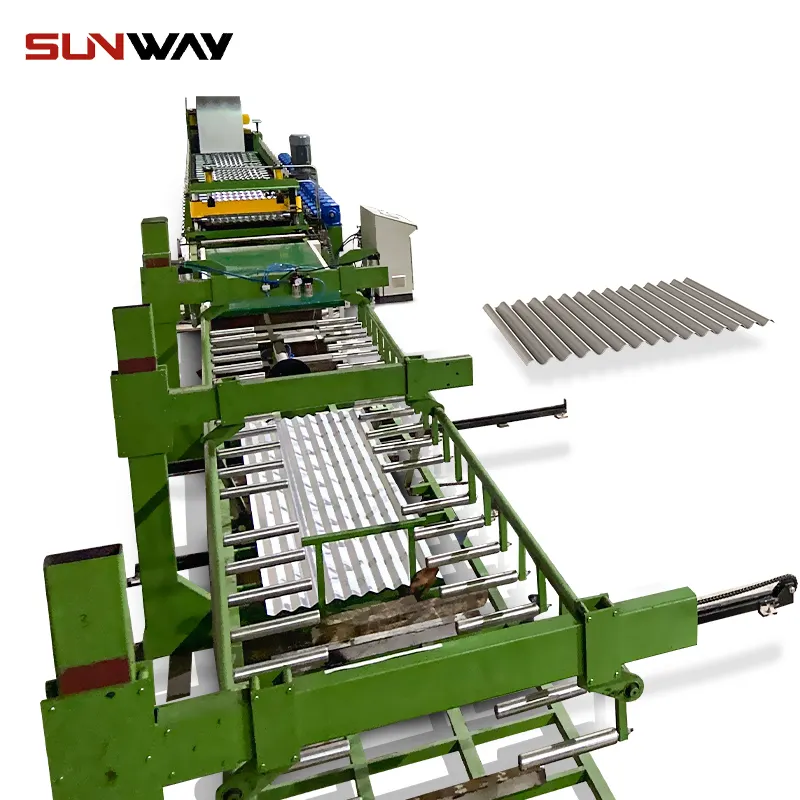

Self-supported steel deck whole set production line consists of truss welding line, bottom panel forming machine board spot welding machine, combining mechanism, electricity, hydraulic and pneumatics with microcomputer control, it performs whole set production process of steel moulding boards truss, galvanized steel forming and assembling & welding. The lines annual single-round production capacity reaches 300000 square meters.

Applications of Steel Truss Roll Forming Machine

Self-supported steel deck panel is a new type steel structure building material developed for steel construction industry in recent years. It's now widely applied in steel structural floor deck, bridge, railway and many other places.

Process Flow of Steel Truss Roll Forming Machine

Roll Forming / Truss Making ---- Assembling and Feeding ---- Spot Welding ---- Run Out Table

Technical Parameters of Steel Truss Roll Forming Machine

Machine Configurations of Steel Truss Roll Forming Machine

Machine Configurations of Steel Truss Roll Forming Machine

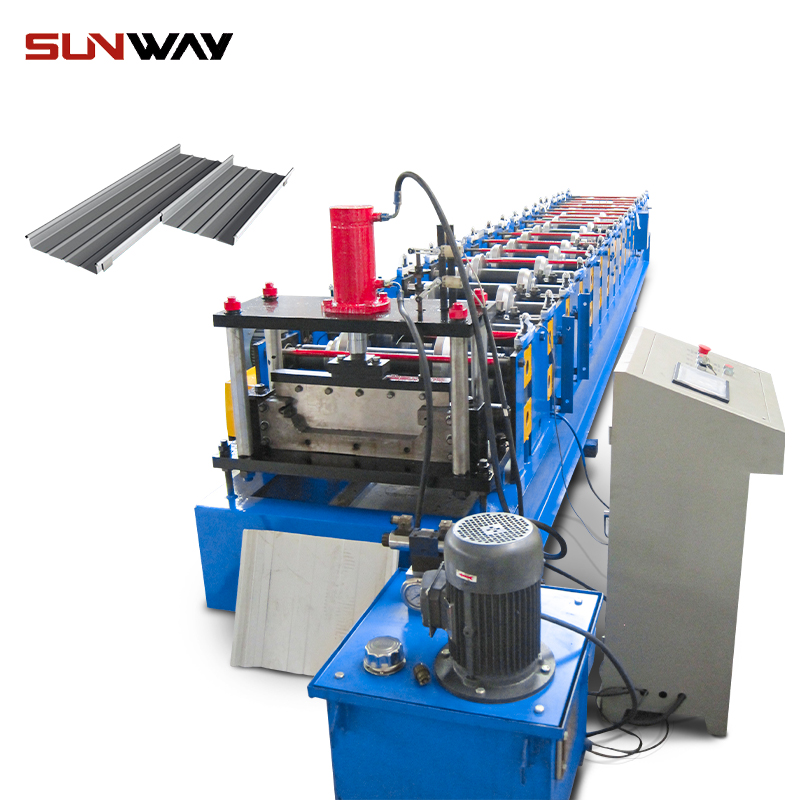

1. Steel Wire Truss Making Machine

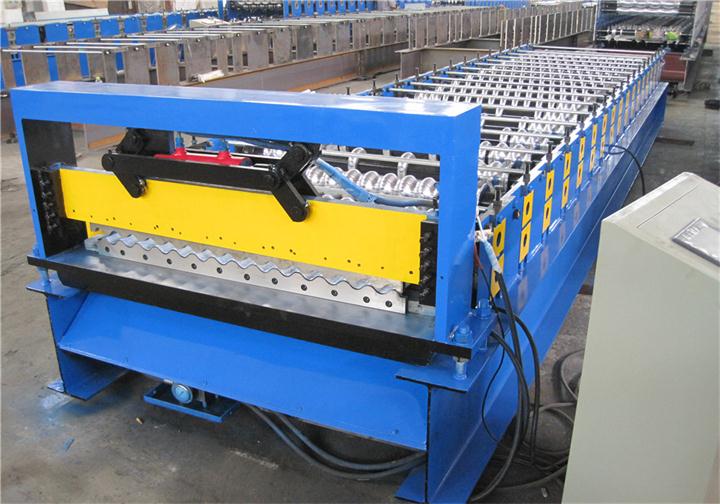

2. Roll Forming Machine

3. Assembling Machine

4. Tables

Machine Model and Name | Parameter | ||

JGH30 Steel Bar Truss Production Line | Suitable Raw Material | First Quarter Main Tendon | Screw Thread Steel Without Rib |

Φ6~14mm | |||

Last Quarter Main Tendon | Screw Thread Steel Without Rib | ||

Φ5~14mm | |||

Z Type Assistant Bar | Round Steel | ||

Φ4~6.5mm | |||

Processing Dimension | First Quarter Height | 70~270mm | |

Last Quarter Height | 15~30mm (Curve Truss) | ||

0~30mm (Straight Truss) | |||

Length | 2000~12000mm | ||

Bottom Width | 135~140mm (Curve Truss) | ||

60, 80 (Straight Truss) | |||

Feet Distance | 200mm | ||

Feet Folding Length | 30mm | ||

Production Speed | 10~15m/min | ||

Total Power | 585Kw | ||

Dimension (L×W×H) | 40000mm×5000mm×4500mm | ||

HG-576 Bottom Plate Forming Machine | Suitable Raw Material | Type | Galvanized Steel |

Thickness | 0.4~1mm | ||

Forming Speed | 12~15m | ||

Dimension (L×W×H) | 10000mm×1700mm×1000mm | ||

JGH60 Steel Moulding Board Spot Welding Machine | Suitable Workpiece Dimension | Roll Formed Steel Plate Width | 576mm |

Steel Bar Truss Max. Height | 270mm | ||

Workpiece Length | 1800~12000mm | ||

Max. Total Speed | 5.5m/min | ||

Total Power | 603Kw | ||

Dimension (L×W×H) | 19000mm×1700mm×2000mm | ||