-

tel:

+86-13616182007 -

email:

E-mail:sales@wuxisunway.com

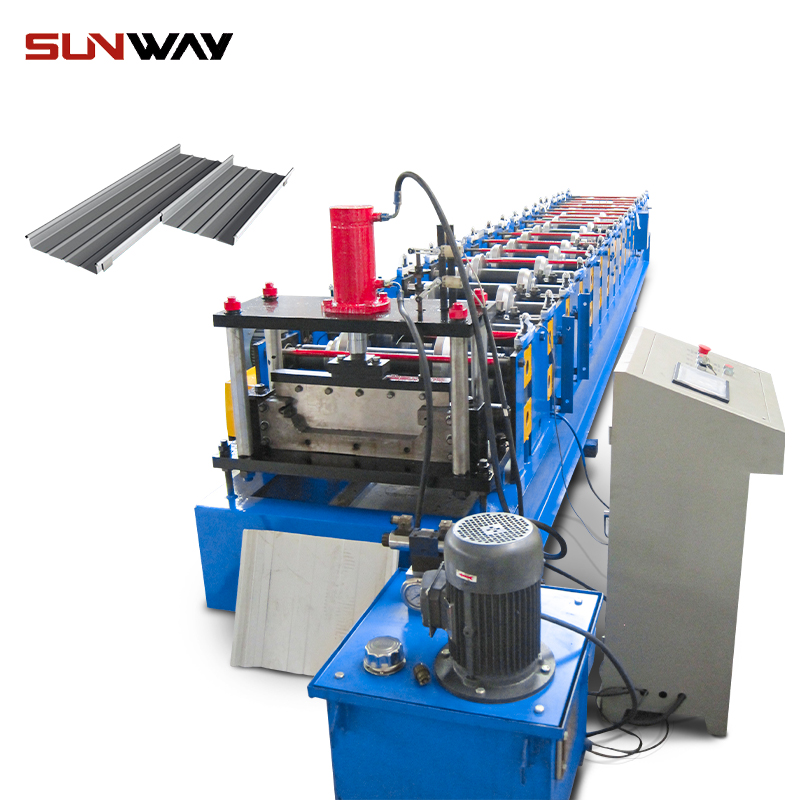

ERW 76 Tube Mill Line & Pipe Mill Machine

ERW 76 high frequency longitudinal welded pipe production line tube mill is designed to produce

welded pipes of 12.7mm-76mm in OD and 0.7mm-3.0mm in wall thickness, as well as

corresponding square and rectangular pipe.

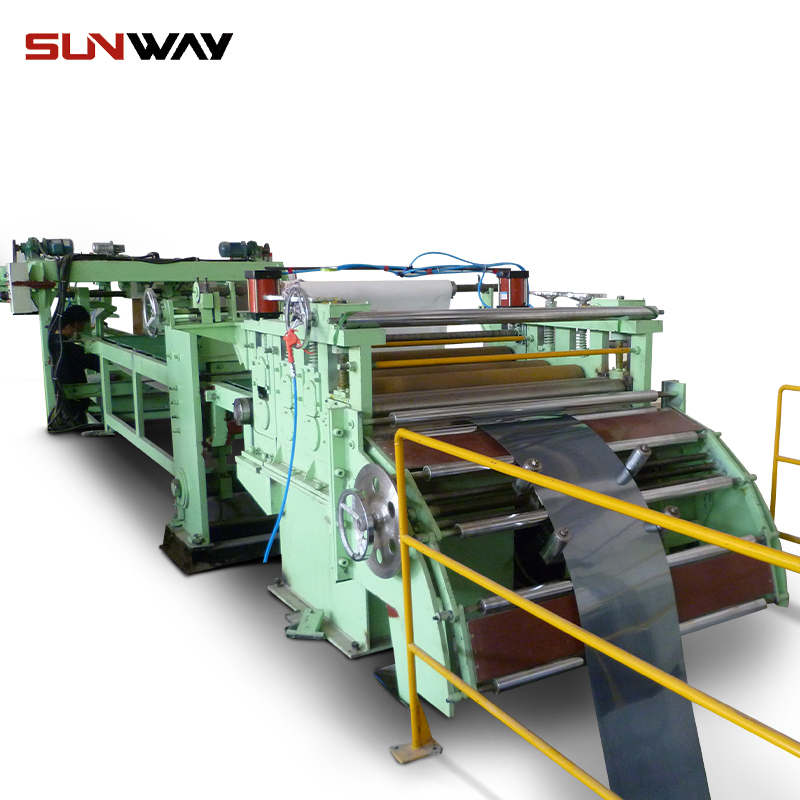

Double Cone Decoiler

Configuration: two cones, hydraulic expansion and contraction

Inner diameter of coil.: Φ508 mm

Outer diameter of coil.: ≤Φ1600mm

Material width: 37~240mm

Coil weight: ≤2.5 tons

Brake type: steam-driven two-phase brake

Double cone exchange: manual 180°rotation

Tube Mill Acuumulator

Outer diameter: 4.2 meters

Metal belt width: 37~240mm

Metal belt thickness: 0.7~3.0mm

Feeding speed: ≥150m/min

Configuration: frame, feeder (11kw AC motor), main body (15kw AC motor)

Feeding control: the feeding is manually controlled, the unwinding is a non-powered way

Vertical Horizontal Accumulator Tube Mill Forming And Sizing

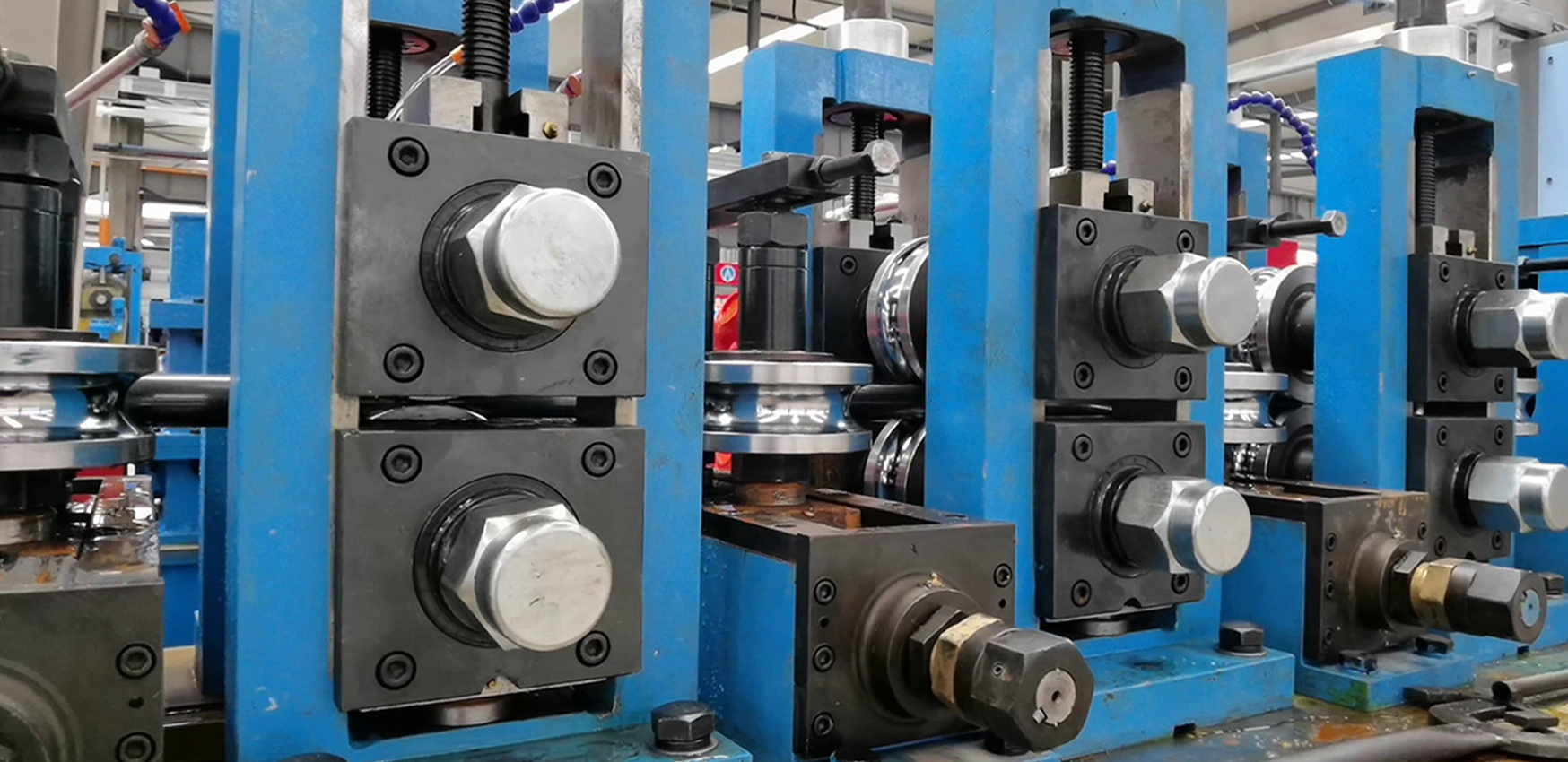

Forming and sizing part

Drive system 1 set

Two-stage transmission 12 sets

Feeding and leveling device 1 set

Flat roller rack 12 sets

Vertical Roller Frame 16 sets

Drive system

Forming and sizing drive system: 1 set

Motor type: 132kw/1000 rpm

Reducer type: ZLY hard gear reducer

Motor drive system: controlled by DC-digital converter

Tube Mill Welding Machine

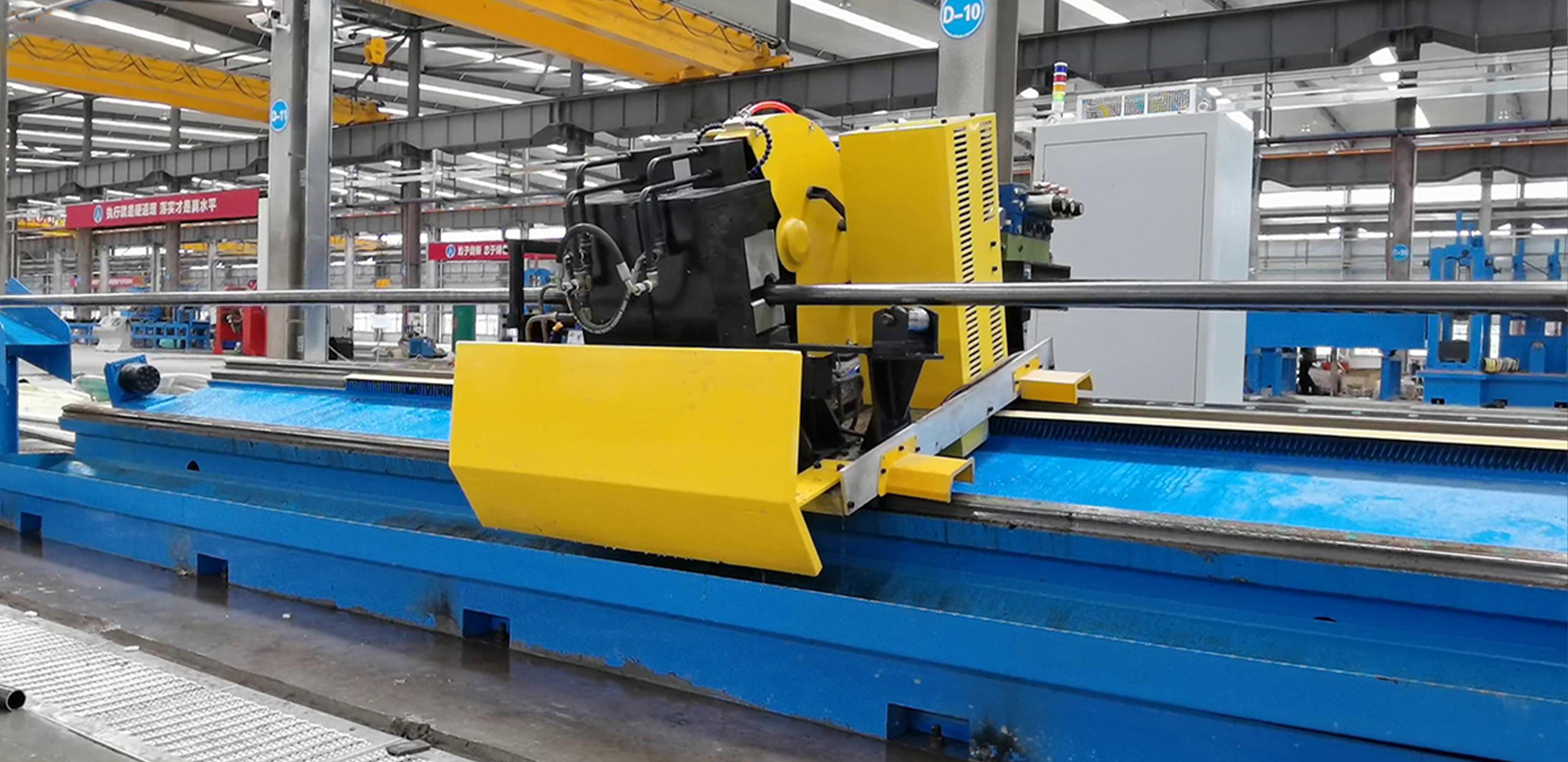

Hot Gringding Computer Saw

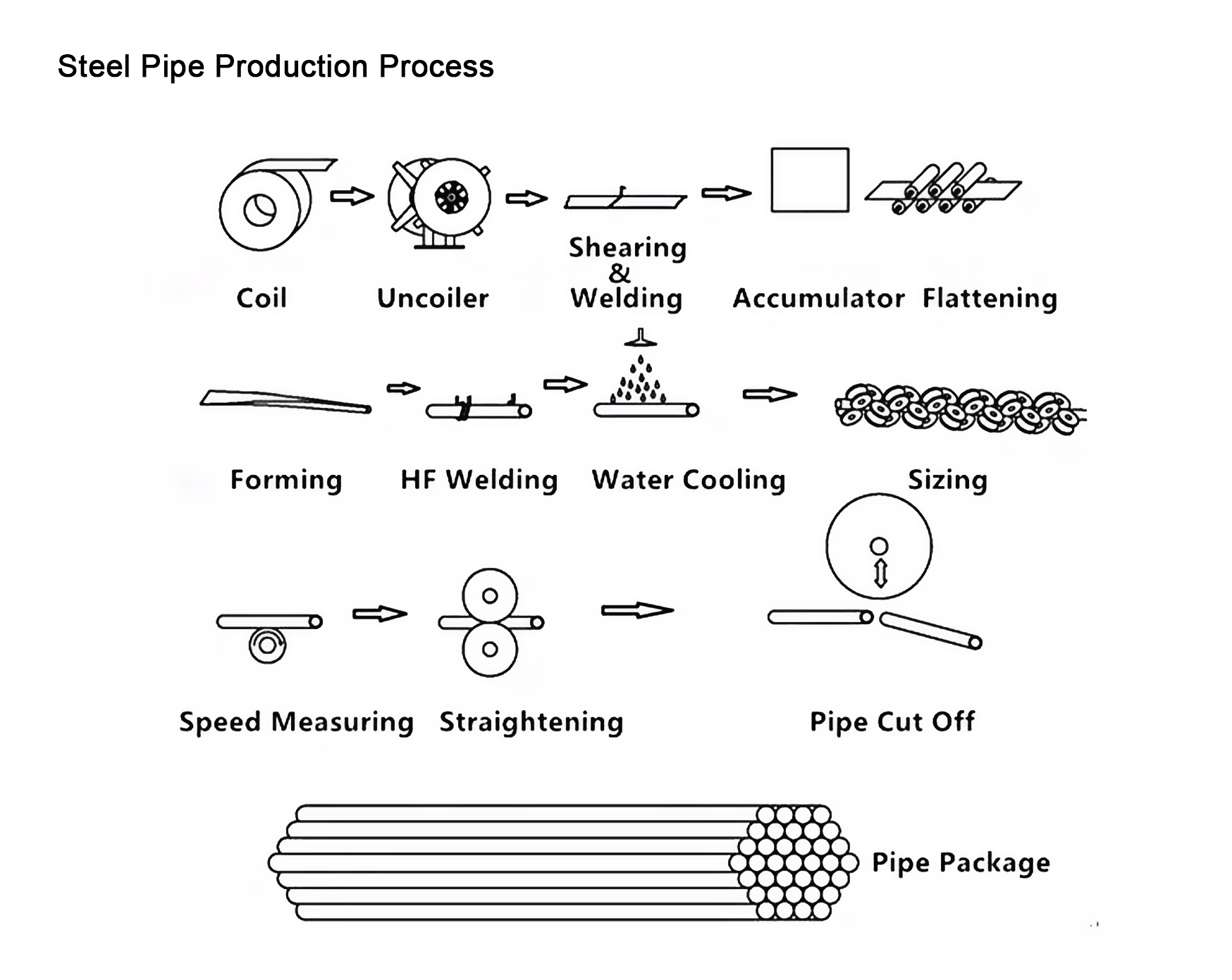

Scrolling Up → Uncoiling → Shear And Welding → Spiral Accumulator→ Forming → H.F. Induction Welding

→ External Burr Removing → Cooling → Sizing → Flying Saw → Run Out Table →Inspecting→ Packing→

Warehouse

Low wastage, low unit wastage and low production cost.

High accuracy, diameter error is only 0.5/100 of the pipe OD.

High production efficiency, line speed can be up to 120m/min.

| Item | Parameter | Thickness |

|---|---|---|

| Round Pipe | 12.7mm-76mm | 0.7mm-3.0mm |

| Square & Rectangle Tube | 25mm*25mm-60mm*60mm | 1.2mm-3.0mm |

| Length | 6m-12m Length Tolerance: ±3mm | |

| Production Speed | 20-120 m/min | |

| Production Capacity | 20,000 ton/year | |

| Carbon Steel Coil | Q235B(ASTM GR·D,σs 230) | |

| Width | 105mm-240mm | 1.2mm-4.0mm |

| Coil ID | 450-520mm | |

| Coil OD | Max 1600mm | |

| Coil Weight | 2.0T | |

| Mill Installed Capacity | 120Kw | |

| Line Area | 70m(Length)*4m(Width) | |

WUXI SUNWAY MACHINERY CO.,LTD is a professional manufacturer and exporter that are

concerned with the design, development and production of cold roll forming machines. All

products comply with international quality standards and are greatly appreciated in variety of

different markets throughout the world, such as Asia, Africa, Europe, South America, and Australia

and so on. It has gained a global sales network.

Our machines feature beautiful appearance, long service life, good performance, simple operation,

reasonable price, good quality and so on. Strong technical resources are the most stable guarantee

for our products' quality. Our company is specialized in manufacturing different kinds of cold roll

forming machines, such as color steel sheet forming machines for roof & wall, C and Z purling

machines for steel structure, steel profiles forming machines for professional applications, slitting

machines for processing raw material, especially in manufacturing Solar Mounting Bracket Machines

which are widely used in Photovoltaic field.

SUNWAY always adhere to Dedication, Unity, Innovation, Win-win situation, as spirit of enterprise.

In accordance with High Quality Assurance and Valued Credibility, we provide customers high

qualified and reliable products with complete after-sales service. Our company is looking forward

to establishing successful and long-term business relationships with all clients around the world in

the near future.

A:We are factory with professional production team and service consciousness just for

exporting various types of roll forming machine.

Q: Do you have after sales support?

A: Yes, we are available online to give guidance and also have skilled technicians to dispatch to

customers' factories.

Q: What's your payment terms?

A: 30% deposit is paid before production, the balance paid after inspection confirmation before

shipment.

Q: What can you do if the machine broken?

A: The quality of our machines is very reliable. The warranty is one year after delivery, if some

parts are broken, we will send you new ones for free and customer affords the express cost. If

some parts are broken out of warranty period, we will sell them at cost.

Q: Do you sell only standard machines?

A: No, most of our machines are designed according to customers'specifications, using famous

brand components.

Q: How to visit our company?

A: Fly to Shanghai airport: By high speed train from Shanghai to Wuxi (30 min),then we can pick

up you.