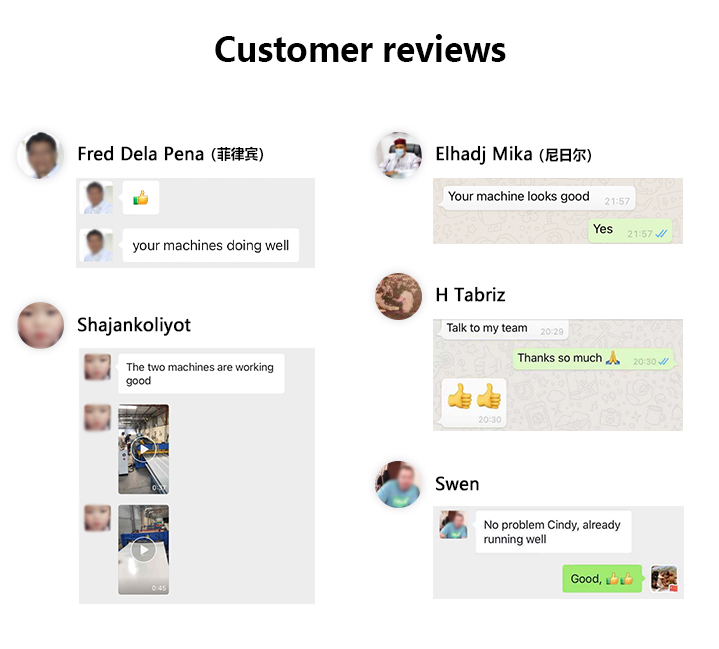

WUXI SUNWAY MACHINERY CO.,LTD is a professional manufacturer and exporter that are concerned with the design, development and production of cold roll forming machines. All products comply with international quality standards and are greatly appreciated in variety of different markets throughout the world, such as Asia, Africa, Europe, South America, and Australia and so on. It has gained a global sales network.

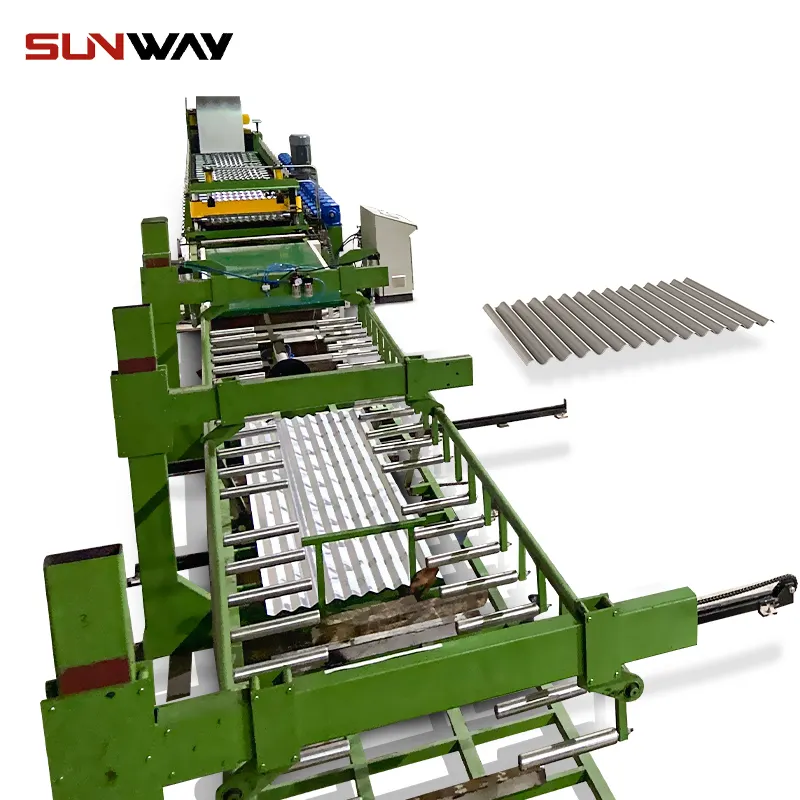

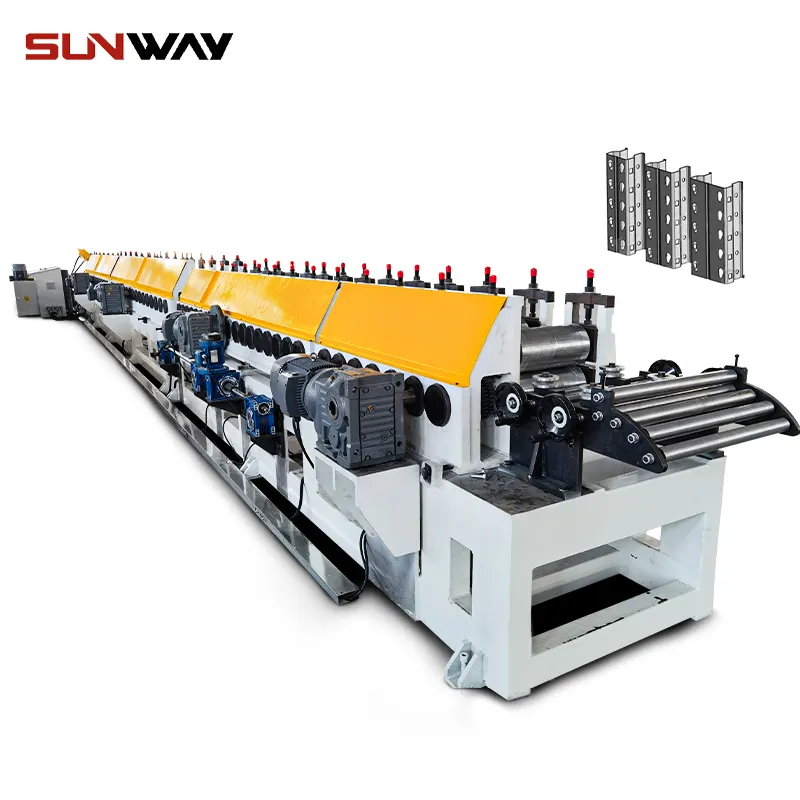

Our machines feature beautiful appearance, long service life, good performance, simple operation, reasonable price, good quality and so on. Strong technical resources are the most stable guarantee for our products' quality. Our company is specialized in manufacturing different kinds of cold roll forming machines, such as color steel sheet forming machines for roof & wall, C and Z purling machines for steel structure, steel profiles forming machines for professional applications, slitting machines for processing raw material, especially in manufacturing Solar Mounting Bracket Machines which are widely used in Photovoltaic field.

SUNWAY always adhere to Dedication, Unity, Innovation, Win-win situation, as spirit of enterprise. In accordance with High Quality Assurance and Valued Credibility, we provide customers high qualified and reliable products with complete after-sales service. Our company is looking forward to establishing successful and long-term business relationships with all clients around the world in the near future.