-

tel:

+86-13616182007 -

email:

E-mail:sales@wuxisunway.com

Dounspout Roll Forming Machine

Downspout roll forming machine is used to produce downspout in rainwater goods system. Normally thickness of

downspout and gutter could be 0.4mm-0.8mm, 0.8-1.5mm or as you requested with raw material: Aluminum, Galvanized

steel, Painted steel, Galvalume, Stainless steel, etc.

There are square pipe roll forming machine (rectangular downspouts roll forming machine) and round pipe roll forming

machine (round corrugated downspouts roll forming machine) also a separate elbow machine.

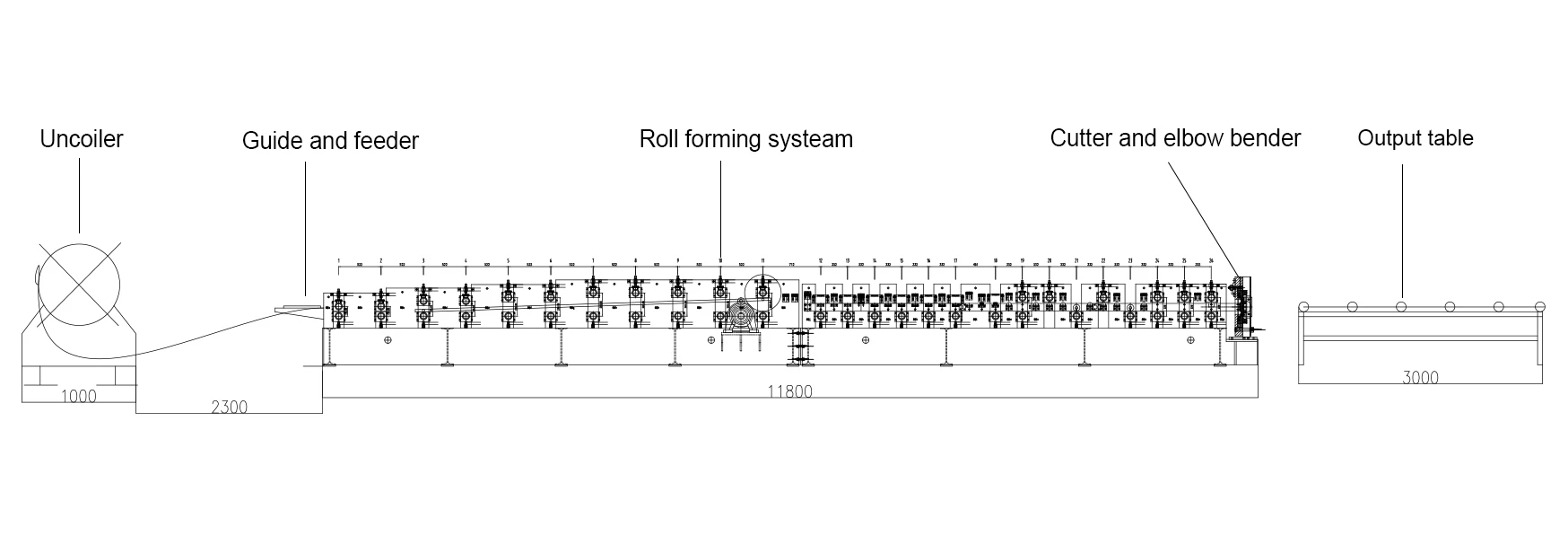

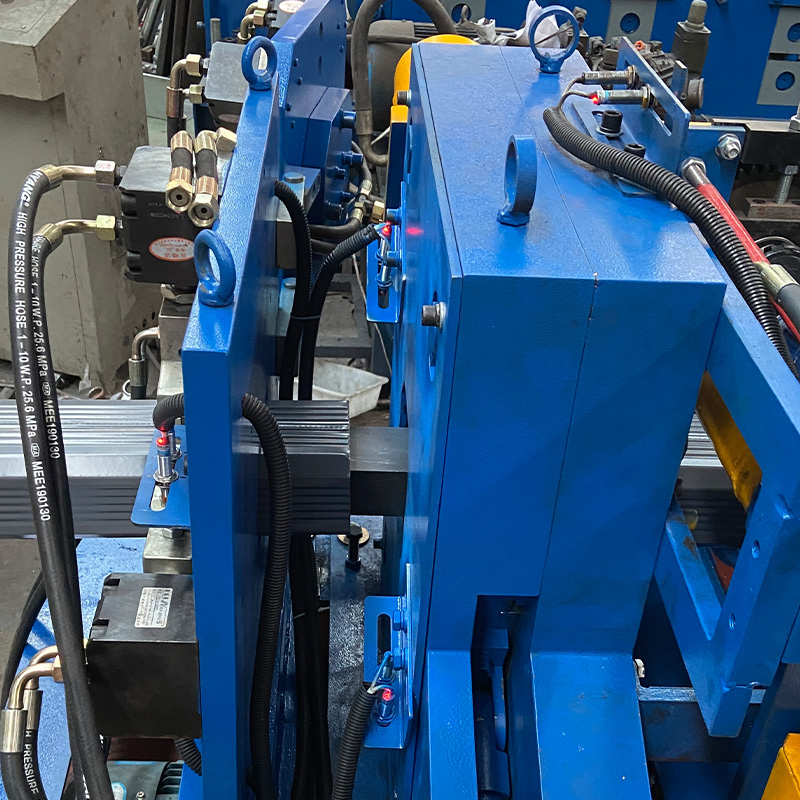

In rainwater goods system, we are able to manufacture more machines like gutter roll forming machine, etc.Our downspout roll forming machine mainly consists of uncoiler, roll forming system, cutting equipment, hydraulic

system, control system and out table. It can make curve for down pipe to meet the requirement of practical engineering

projects.

In Construction Industries, we are able to manufacture more machines like main channel roll forming machine, purlin roll

forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, top hat roll forming

machine, clip roll forming machine, metal deck (floor deck) roll forming machine, roof/wall panel roll forming machine, roof tile

roll forming machine, corrugated roll forming machine, ridge cap roll forming machine, downspout roll forming machine, etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one

service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you

obtain perfectly functional profiles.

Dounspout Roll Forming Machine | ||

Machinable Material | A) Galvanized Coil | Thickness(MM): 0.3-0.8 According To Your Requirment |

B) PPGI, PPGL | ||

Yield Strength | 250 - 350 Mpa / 350-550Mpa | |

Tensil Stress | 350 Mpa-550 Mpa | |

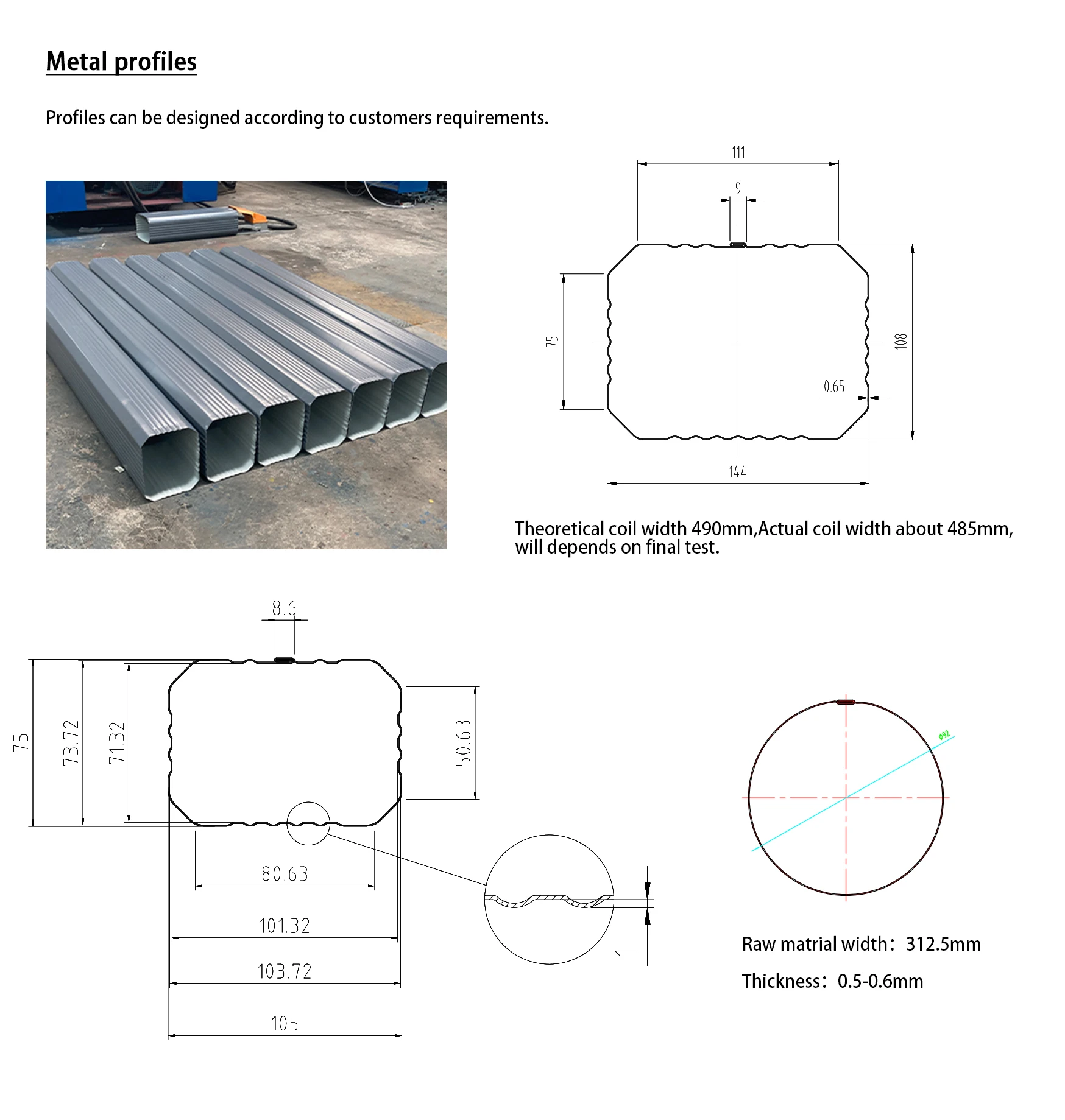

Coil Width | As Per The Detailed Profile | |

Forming Speed | 10-15 m/min | * Or According To Your Requirment |

Forming Station | 18-24 Stations | * According To Your Profile Drawings |

Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

Driving System | Chain Drive | * Gearbox Drive (Optional) |

Machine Structure | Steel Plates Welded | * Individual Station (Optional) |

Rollers’ Material | 45# | |

Cutting System | Hydraulic Post Cut | * Hydraulic Servo Tracking Cutter (Optional) |

Output Way | Roller Table | |

Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

Power Supply | 380V 50Hz | * Or According To Your Requirment |

Machine Color | Industrial Blue | * Or According To Your Requirment |

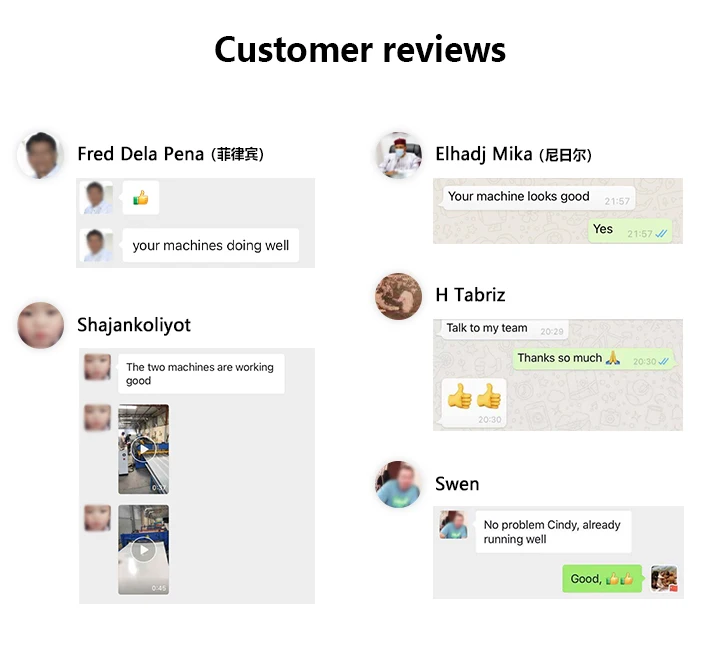

WUXI SUNWAY MACHINERY CO.,LTD is a professional manufacturer and exporter that are concerned with the design,

development and production of cold roll forming machines. All products comply with international quality standards and are

greatly appreciated in variety of different markets throughout the world, such as Asia, Africa, Europe, South America, and

Australia and so on. It has gained a global sales network.

Our machines feature beautiful appearance, long service life, good performance, simple operation, reasonable price, good

quality and so on. Strong technical resources are the most stable guarantee for our products' quality. Our company is

specialized in manufacturing different kinds of cold roll forming machines, such as color steel sheet forming machines for

roof & wall, C and Z purling machines for steel structure, steel profiles forming machines for professional applications, slitting

machines for processing raw material, especially in manufacturing Solar Mounting Bracket Machines which are widely used

in Photovoltaic field.

SUNWAY always adhere to Dedication, Unity, Innovation, Win-win situation, as spirit of enterprise. In accordance with High

Quality Assurance and Valued Credibility, we provide customers high qualified and reliable products with complete after-sales

service. Our company is looking forward to establishing successful and long-term business relationships with all clients

around the world in the near future.

A:We are factory with professional production team and service consciousness just for exporting various types of laser

machine.

Q: Do you have after sales support?

A: Yes, we are available online to give guidance and also have skilled technicians to dispatch to customers’ factories.

Q: What's your payment terms?

A: 30% deposit is paid before production, the balance paid after inspection confirmation before shipment.

Q: What can you do if the machine broken?

A: The quality of our machines is very reliable. The warranty is one year after delivery, if some parts are broken, we will

send you new ones for free and customer affords the express cost. If some parts are broken out of warranty period, we

will sell them at cost.

Q: Do you sell only standard machines?

A: No, most of our machines are designed according to customers’ specifications, using famous brand components.

Q: How to visit our company?

A: Fly to Shanghai airport: By high speed train from Shanghai to Wuxi (30 min),then we can pick up you.