-

tel:

+86-13616182007 -

email:

E-mail:sales@wuxisunway.com

Thick Plate Slitting Line

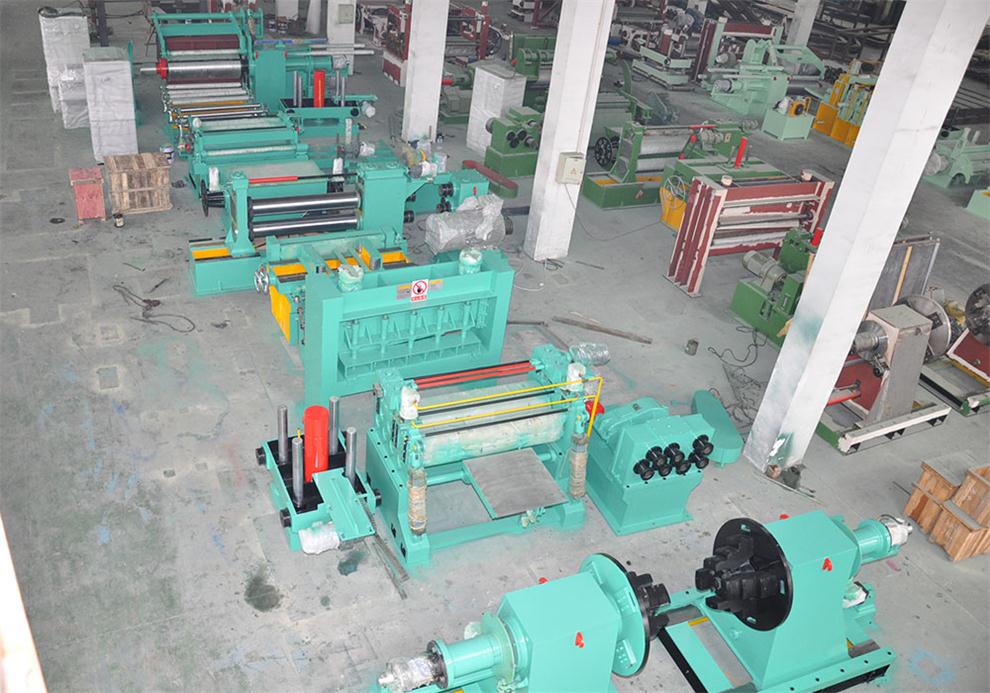

This thick plate slitting line, also called metal coil slitter, is able to slit thick steel master coil into small baby coils. The thick coil slitting line is composed of: coil-loading car

We can also supply the customized machines.

Introduction:

This thick plate slitting line, also called metal coil slitter, is able to slit thick steel master coil into small baby coils. The thick coil slitting line is composed of: coil-loading car, double mandrel big-load uncoiler, portal style coil-head guide, press and shovel equipment, double roller pinching feeder, five-roller leveler, end-cutter, Roll table, Central aligner, Disc slitter, scrap winder, hole accumulator, pre-separator& tensioner, Portal style coils-separator and presser, recoiler, coil unloading car, hydraulic control, and electric control.

Capacity of different models of thick sheet slitting lines (metal coil slitter):

Strip thickness: (3~12) mm, (4-16)mm, (5~20) mm;

Strip width: 500-1800mm, 800~2000mm or 1000~2200mm.

Advantages and Characteristics of Coil Slitting Machine:

1. For thick sheet slitting machine, strength and solidity is very important. We take much attention to metal coil slitter's structure design and coil slitting machine's material usage, for example: portal style coil-head guide and press, dual-body scrap reeler, five-roller tensioner for recoiling, portal-style coils pressing & separating bracket, etc.

2.Double cone-mandrel decoiler, not only to bear big coils such as 35T or 40T, but also convenient for loading coil onto the decoiler.

3.Coil-loading car has support platform with twp rotatable rollers at edge edges, while loading coil onto double-cone decoiler, on one hand, solidly support a big coil; on the other hand, double rollers on coil car platform rotate synchronously with decoiling mandrel.

4.Strength of all rollers and shafts increase with steel strip thickness.

5.Dual-body scrap winders are driven by two torque motors and two speed reducers.

6.Recoiling tensioner of the metal coil slitter, or sheet slitting line,adopts solid five-roller tensioning structure, providing stable and even tension for recoiling.

7.Coils pusher is installed on recoiler, to push coils out whiling discharging slit coils.

8.AC motors and speed reducers drive pinch-feeder & five-roller leveler and five-roller tensioner, while DC motors & speed reducers drive slitter and recoiler.

9.Coil slitting machine's electric control: Parker Eurotherm 590 speed controller + PLC control.

Detail specification of Coil Slitting Machine:

1. SW-(3-12)×1800mm Sheet Slitting Line

Material of coils: HR/CR carbon steel, galvanized plate, colored steel plate etc.

Metal Coil Slitter Strip thickness: (3~12) mm

Coil Slitting Machine Strip width: 500~1800mm

Max.coil weight: 35000kgs

Diameter of leveling rollers & tensioning roller: Φ210

Metal Coil Slitter Diameter of slitter shaft: Φ300

Disc cutters: 6CrW2Si, HRC56°~58°, OD500mm x ID300mm x T25mm.

Diameter of recoiler block: Φ610mm

Separating discs: 65Mn, OD250 x ID95 x T10/20mm

Coil Slitting Machine DC motors for slitter and recoiler: 160KW, 200KW.

Metal Coil Slitter speed: (0~30) m/min, adjustable

3.SW-(4-16)×2200mm Sheet Slitting Line

Material of coils: HR/CR carbon steel such as Q235, galvanized plate, colored steel plate etc

Strip thickness: (4~16) mm

Metal Coil Slitter Strip width: 800~2200mm

Coil Slitting Machine Max.coil weight: 40000kgs

Diameter of leveling rollers & tensioning roller: Φ230

Diameter of slitter shaft: Φ360

Metal Coil Slitter Disc cutters: 6CrW2Si, HRC54°~56°, OD600mm x ID360mm x T50mm.

Diameter of recoiler block: Φ760mm

Coil Slitting Machine Separating discs: 65Mn, OD250 x ID110 x T10/20mm

DC motors for slitter and recoiler: 200KW, 250KW.

Slitting speed: (0~30) m/min, adjustable

2.SW-(5-20)×2000mm Sheet Slitting Line

Material of coils: HR/CR carbon steel such as Q235, galvanized plate, colored steel plate etc

Metal Coil Slitter Strip thickness: (5~20) mm

Strip width: 800~2000mm

Max.coil weight: 40000kgs

Diameter of leveling rollers & tensioning roller: Φ260

Metal Coil Slitter Diameter of slitter shaft: Φ420

Coil Slitting Machine Disc cutters: 6CrW2Si, HRC54°~56°, OD650mm x ID420mm x T50mm.

Diameter of recoiler block: Φ800mm

Separating discs: 65Mn, OD250 x ID110 x T10/20mm

DC motors for slitter and recoiler: 280KW, 315KW.

Coil Slitting Machine Slitting speed: (0~20) m/min, adjustable

Specifications of Metal Coil Slitter:

| Model | Thickness | Width | Coil Weight | Finished slit width | Max Slitting speed |

| SW-12 x 1800 | 3-12mm | 600-1800mm | Max 35T | Min. 60mm | 30m/min |

| SW-16 x 2200 | 4-16mm | 800-2200mm | Max 40T | Min. 100mm | 30m/min |

| SW-20x 2000 | 5-20mm | 800-2000mm | Max 40T | Min 100mm | 20m/min |

| Note: The data in the form just as reference according to general ranges, we always design and make each sheet slitting line according to each customer's specific requirements, so each customer can buy his own well-content coil slitting machine from us. | |||||