-

tel:

+86-13616182007 -

email:

E-mail:sales@wuxisunway.com

X1600 Slitting Line

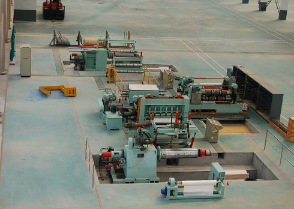

This Slitting Line (i.e. metal coil slitting machine/ slitter line) is used for processing the coil into narrow steel strips

with desired width.

This line is adaptable to process cold-rolled and galvanized coils, silicon steel coil, stainless coils, pre-painted coils,

aluminum coils, and all sorts of plate and coated coils. And it is widely applies to many industries like automobiles,

containers, household appliances, food packing, construction material etc.

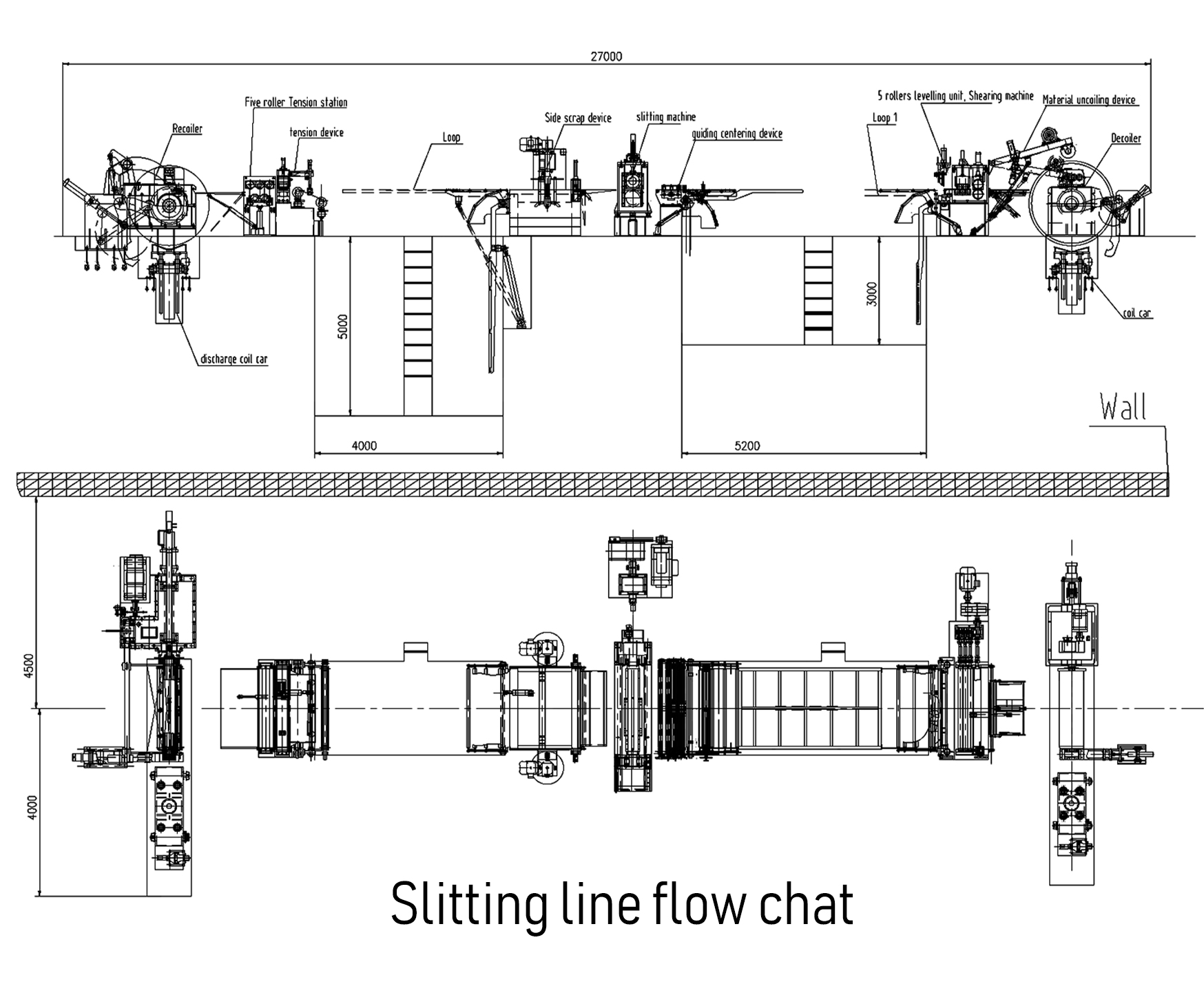

It consists of coil lifter, decoiler, slitter, scrap recoiler, damping device, recoiler etc, accompany of feeder, loop bridge,

pinch etc.

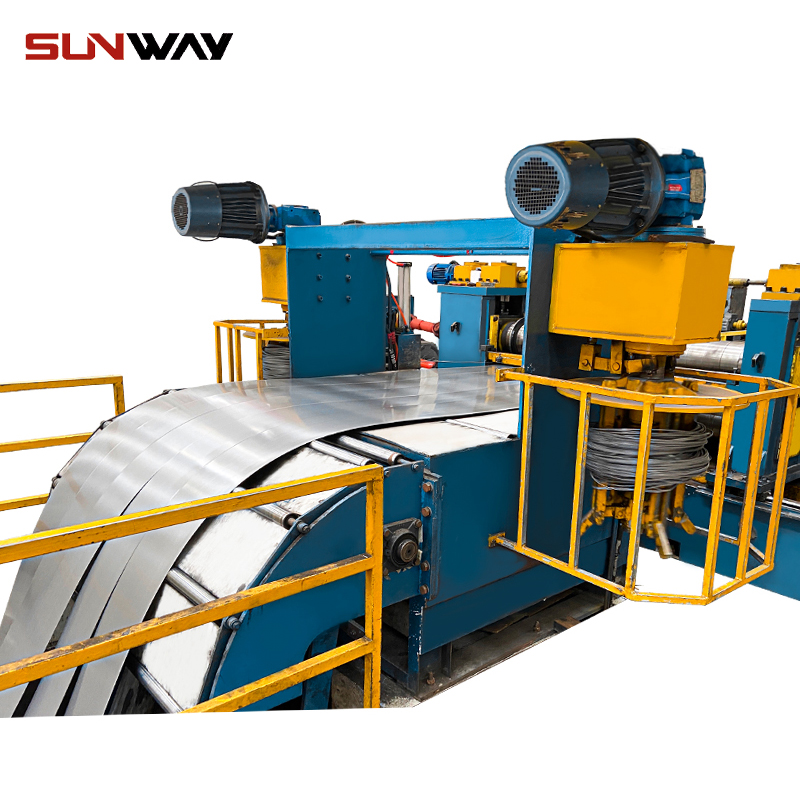

It can be complemented by additional slitting unit that provides rapid change of blades. The slitting units are moved

inline and offline by rails and the whole process is controlled from the control panel.

* Easy operation, highly automated and high production efficiency* High availability* Low operating costs* High automation

level to reduce non-productive times* Flexibility from customer-specific arrangement and design* High quality of the final

product

Metal Coil Slitting Machine / Slitter Line | ||

Applicable Material | Galvanized Steel Coil / Cold-rolled Steel Coil | |

Material Of Thickness | 0.3-3.0mm | |

Width Of Material | 500-1500mm (Max) | |

Inner Diameter Of Steel Coil | Ф508mm, Ф610mm(With Rubber Ring) | |

Outer Diameter Of Steel Coil | Ф1800mm (Max) | |

Weight Capacity Of Steel Coil | 16T (Max) | |

Inner Diameter Of Recoiler | Ф508mm | |

Diameter Of Blade Shaft | Ф240mm, Material is 40Cr | |

Size Of Slitting Blade | Ф200×Ф340×10mm | |

Material Of Slitting Blade | H13K | |

Machine Running Speed | 0-150m/min | |

Slitting Strips | 10 Strips Max While 3mm Thickness | |

Slitting Width Tolerance | ±0.10mm | |

Min Slitting Width | 20mm | |

Recoiler Weight | 16 Ton (Max) | |

Recoiler Inner Diameter | Ф508mm | |

Recoiler Outer Diameter | Ф1800 (Max) | |

Power Source | 380V/50Hz/3Ph | |

Total Power | About 300KW | |

Floor Area | About 24000×13000mm | |

Required Operator | 1 Technician 2-3 Workers | |

WUXI SUNWAY MACHINERY CO.,LTD is a professional manufacturer and exporter that are concerned with the design,

development and production of cold roll forming machines. All products comply with international quality standards and

are greatly appreciated in variety of different markets throughout the world, such as Asia, Africa, Europe, South America,

and Australia and so on. It has gained a global sales network.

Our machines feature beautiful appearance, long service life, good performance, simple operation, reasonable price,

good quality and so on. Strong technical resources are the most stable guarantee for our products' quality. Our company

is specialized in manufacturing different kinds of cold roll forming machines, such as color steel sheet forming machines

for roof & wall, C and Z purling machines for steel structure, steel profiles forming machines for professional applications,

slitting machines for processing raw material, especially in manufacturing Solar Mounting Bracket Machines which are

widely used in Photovoltaic field.

SUNWAY always adhere to Dedication, Unity, Innovation, Win-win situation, as spirit of enterprise. In accordance with High

Quality Assurance and Valued Credibility, we provide customers high qualified and reliable products with complete

after-sales service. Our company is looking forward to establishing successful and long-term business relationships with

all clients around the world in the near future.

A:We are factory with professional production team and service consciousness just for exporting various types of roll

forming machine.

Q: Do you have after sales support?

A: Yes, we are available online to give guidance and also have skilled technicians to dispatch to customers’ factories.

Q: What's your payment terms?

A: 30% deposit is paid before production, the balance paid after inspection confirmation before shipment.

Q: What can you do if the machine broken?

A: The quality of our machines is very reliable. The warranty is one year after delivery, if some parts are broken, we

will send you new ones for free and customer affords the express cost. If some parts are broken out of warranty

period, we will sell them at cost.

Q: Do you sell only standard machines?

A: No, most of our machines are designed according to customers’ specifications, using famous brand components.

Q: How to visit our company?

A: Fly to Shanghai airport: By high speed train from Shanghai to Wuxi (30 min),then we can pick up you.