-

tel:

+86-13616182007 -

email:

E-mail:sales@wuxisunway.com

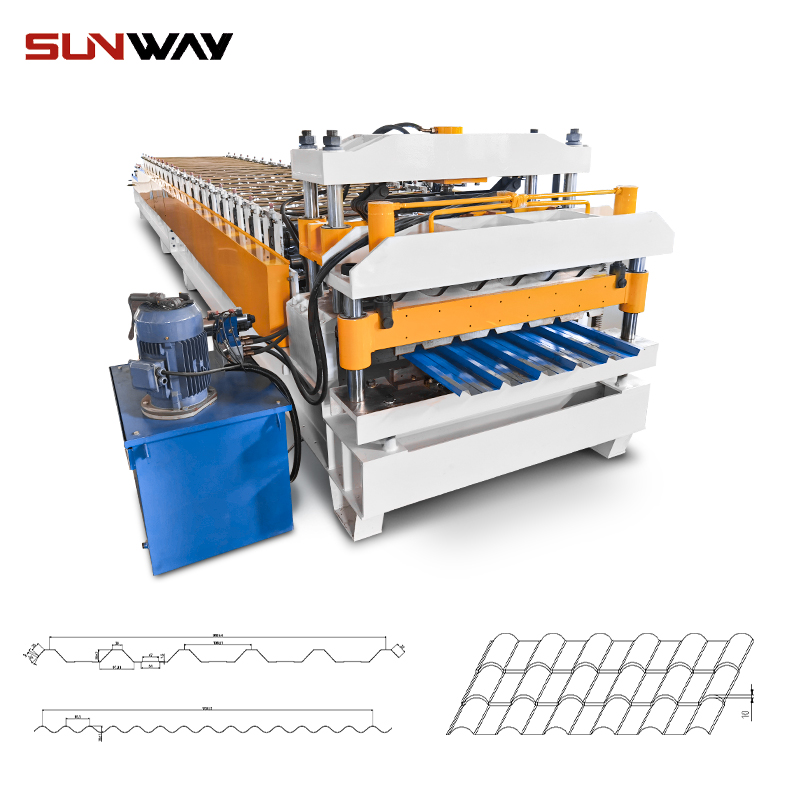

WYQ24 Half Hydraulic Profile Bending Machine

This type of machine belongs to half hydraulic profile bending machine.It is commonly applied in the fields

of petrol,chemical, shipyard, metal working and machine manufacturing industries.

Bending and checking circle will be completed as long as the machine starts feeding. Actually,two bottom

rollers are fixed and hydraulic oil tank always supports top roller to move.Hydraulic motor acts as the power

of three drive rolls.

High-quality bending of asymmetric profiles can be guaranteed with the side guide rollers .This machine not

only has small volume and full function,but also has advanced and reliable structure.It can be classified into

advanced profile bending equipment in the world so far.

* Superior Hardened Shafts From Special Steel Material

* Top Roll Hydraulically Does Movement

* Customer Can Select Horizontal Or Vertical Working Position

* Simply Operate Mobile Control Panel

Technical Data | W24S(WY24-) | ||||||

Max. Bending Resistant Modulus | 6 | 16 | 30 | 45 | 75 | 100 | |

Bending Speed | 6 | 5 | |||||

Yield Limit | S=245Mpa | ||||||

Angle Inner Bending | Max Section Size | 40x5 | 70x8 | 80x8 | 90x10 | 100x10 | 120x12 |

Angle Outer Bending | Max Section Size | 50x5 | 80x8 | 90x10 | 100 | 120x12 | 140x16 |

Channel Outer Bending | Channel Size | 8 | 12 | 16 | 20 | 25 | 28 |

Channel Inner Bending | Channel Size | 8 | 12 | 16 | 20 | 25 | 28 |

Plate Flat Bending | Max Section Size | 100x18 | 150x25 | 180x25 | 200x30 | 220x40 | 250x40 |

Plate Vertical Bending | Max Section Dia | 50x12 | 75x16 | 90x20 | 100x25 | 110x40 | 120x40 |

Tube Bending | Max Section Size | 42x4 | 76x4.5 | 89x5 | 89x8 | 114x5 | 159x5 |

Rod Bending | Max Section Size | 38 | 52 | 62 | 75 | 85 | 90 |

Square Bending | Max Section Size | 45x3 | 60x4 | 70x4 | 98x6 | 90x8 | 100x10 |

Technical Data | W24S(WY24-) | ||||||

Max. Bending Resistant Modulus | 140 | 180 | 260 | 320 | 400 | 500 | |

Bending Speed | 4 | ||||||

Yield Limit | S=245Mpa | ||||||

Angle Inner Bending | Max Section Size | 140x16 | 150x16 | 160x16 | 180x14 | 200x18 | 200x20 |

Angle Outer Bending | Max Section Size | 150x16 | 160x16 | 180x14 | 200x18 | 200x24 | 250x25 |

Channel Outer Bending | Channel Size | 30 | 32 | 36 | 40 | 45 | 50 |

Channel Inner Bending | Channel Size | 30 | 32 | 36 | 40 | 45 | 50 |

Plate Flat Bending | Max Section Size | 280x50 | 300x50 | 330x50 | 360x60 | 400x75 | 500x76 |

Plate Vertical Bending | Max Section Dia | 150x40 | 180x30 | 190x40 | 190x50 | 200x50 | 200x60 |

Tube Bending | Max Section Size | 168x6 | 168x8 | 219x8 | 245x8 | 273x8 | 323x10 |

Rod Bending | Max Section Size | 100 | 110 | 120 | 135 | 150 | 160 |

Square Bending | Max Section Size | 125x10 | 140x10 | 150x10 | 165x10 | 180x12 | 200x12 |

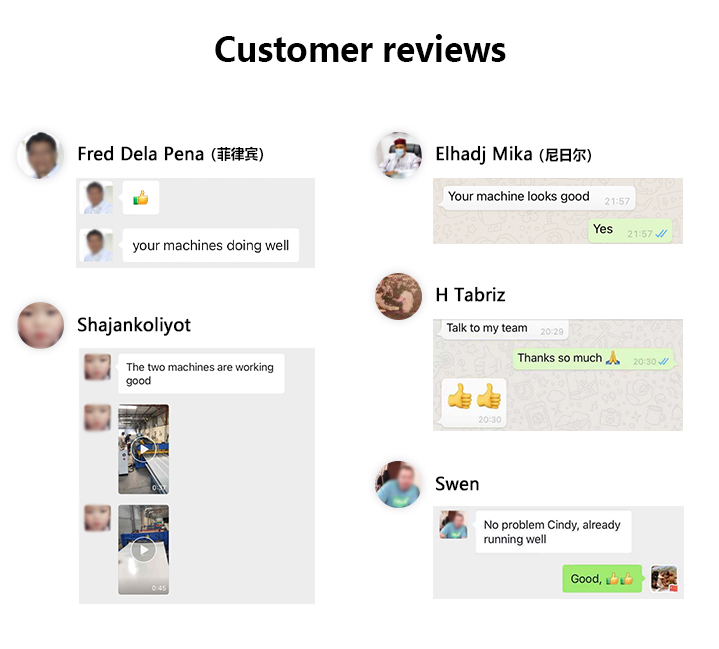

WUXI SUNWAY MACHINERY CO.,LTD is a professional manufacturer and exporter that are concerned with the design,

development and production of cold roll forming machines. All products comply with international quality standards and

are greatly appreciated in variety of different markets throughout the world, such as Asia, Africa, Europe, South America,

and Australia and so on. It has gained a global sales network.

Our machines feature beautiful appearance, long service life, good performance, simple operation, reasonable price, good

quality and so on. Strong technical resources are the most stable guarantee for our products' quality. Our company is

specialized in manufacturing different kinds of cold roll forming machines, such as color steel sheet forming machines for

roof & wall, C and Z purling machines for steel structure, steel profiles forming machines for professional applications,

slitting machines for processing raw material, especially in manufacturing Solar Mounting Bracket Machines which are

widely used in Photovoltaic field.

SUNWAY always adhere to Dedication, Unity, Innovation, Win-win situation, as spirit of enterprise. In accordance with High

Quality Assurance and Valued Credibility, we provide customers high qualified and reliable products with complete

after-sales service. Our company is looking forward to establishing successful and long-term business relationships with

all clients around the world in the near future.

A:We are factory with professional production team and service consciousness just for exporting various types of roll

forming machine.

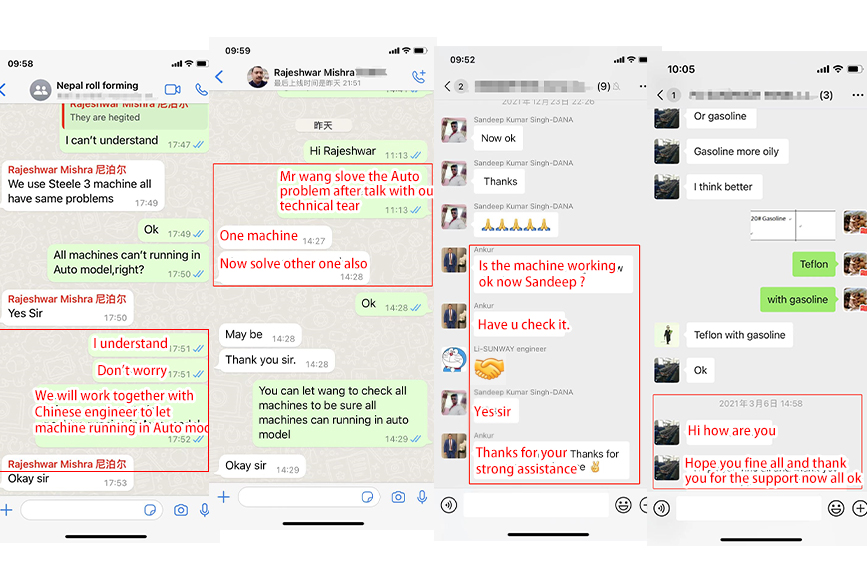

Q: Do you have after sales support?

A: Yes, we are available online to give guidance and also have skilled technicians to dispatch to customers’ factories.

Q: What's your payment terms?

A: 30% deposit is paid before production, the balance paid after inspection confirmation before shipment.

Q: What can you do if the machine broken?

A: The quality of our machines is very reliable. The warranty is one year after delivery, if some parts are broken, we

will send you new ones for free and customer affords the express cost. If some parts are broken out of warranty

period, we will sell them at cost.

Q: Do you sell only standard machines?

A: No, most of our machines are designed according to customers’ specifications, using famous brand components.

Q: How to visit our company?

A: Fly to Shanghai airport: By high speed train from Shanghai to Wuxi (30 min),then we can pick up you.