-

tel:

+86-13616182007 -

email:

E-mail:sales@wuxisunway.com

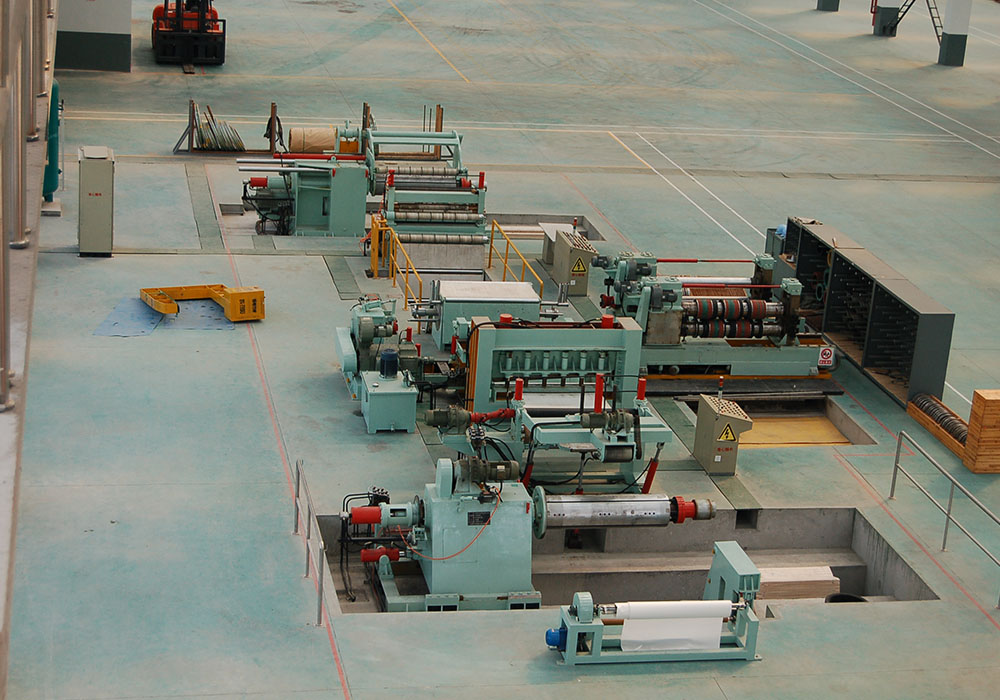

High Speed Slitting Line

High Speed Slitting Line is a slitting line that can decoil a mother (original ) coil, slit the mother (original ) coil into a certain number of small coils, and neatly recoil the slit baby coils at high speed of max 100-150m/min on the premise that slitting

We can also supply the customized machines.

Description:

High Speed Slitting Line is a slitting line that can decoil a mother (original ) coil, slit the mother (original ) coil into a certain number of small coils, and neatly recoil the slit baby coils at high speed of max 100-150m/min on the premise that slitting precision and recoiling uniformity are not ensured.

Solutions Using This High Speed Coil Slitting Line

Case One: 3 x 1250 High speed Slitting Line

Coil material: high strength carbon steel, silicon steel.

Coil thickness: 0.3-3.0mm

Coil width: 300-1250mm

Coils ID, OD: Φ508, 1800mm

Coils weight: max 20T

Capacity of slitting: at 0.3-1.0mm, max 20strips

At 3mm, max 10strips

Speed of slitting: max 100m/min

Slit strip width tolerance: +/-0.03mm

Camber tolerance: +/-0.1mm/m

Hump tolerance: max 0.5mm

Edge scrap width: 3-8mm which depends on customer's coils quality

Delivery time: 90days.

Business process:

Customer visited our company twice and signed contract in 2010.

After machine arrives at customer's company, we sent two engineers to customer to install & debug the slitting line; the slitting line runs very well.

Customer Comment

Customer is very satisfied with our performances, keep contact with us until now.

Case Two: 4 x 1600 High Speed Slitting Line

Coil material: HR/CR carbon steel, galvanized steel, colored steel, etc.

Coil thickness: 0.4-4.0mm

Coil width: 500-1600mm

Coils ID, OD: Φ508, 2100mm

Coils weight: max 30T

Capacity of slitting: at 0.4-1.0mm, max 20strips

At 4mm, max 10 strips

Speed of slitting: ≤2mm, max 120m/min; 2-3mm, 80m/min; 3-4mm, 60m/min

Delivery time: 120days

Business process:

Customer confirmed the order on his first time of visiting our company in 2011.

We sent engineers to customer's factory, the performance of working machine made customer very happy.

Case Three: 6 x 1600 High Speed Slitting Line

Coil material: HR/CR carbon steel, galvanized steel, colored steel, etc.

Coil thickness: 0.6-6.0mm

Coil width: 500-1600mm

Coils ID, OD: Φ480mm-800mm, 2100mm

Coils weight: max 30T

Capacity of slitting: at 0.6mm, max 20strips

At 6mm, max 8 strips

Speed of slitting: thickness ≤ 3mm, max 120m/min; more than 3mm, max 80m/min

Delivery time: 120days

Case Four: 8 x 1600 High Speed Slitting Line

Coil material: HR/CR carbon steel, galvanized steel, colored steel, etc.

Coil thickness: 0.6-8.0mm

Coil width: 500-1600mm

Coils ID, OD: Φ480mm-800mm, 2100mm

Coils weight: max 30T

Capacity of slitting: at 0.6mm, max 20strips

At 8mm, max 8 strips

Speed of slitting: thickness ≤ 3mm, max 120m/min; more than 3mm, max 80m/min

Delivery time: 120days

Business process:

Customer confirmed the order on his first time of visiting our company in 2010, and has already bought two lines from us.

We sent engineers to customer's factory, the performance of working machine satisfy the customer.

Specification Form:

| Model | Thickness | Width | Coil Weight | Finished slit width | Max Slitting speed |

| SW-2×1600 | 0.3-2mm | 800-1600mm | Max 30T | Min. 20mm | 150m/min |

| SW-4×1600 | 0.5-4mm | 800-1600mm | Max 30T | Min. 40mm | 150m/min |

| SW-6×1600 | 1-6mm | 800-1600mm | Max 30T | Min 60mm | 120m/min |

| SW-8×1800 | 2-8mm | 900-1800mm | Max 30T | Min 70mm | 100m/min |

| SW-10×2000 | 3-10mm | 900-2000mm | Max 30T | Min 80mm | 100m/min |

| Note: The data in the form just as reference according to general ranges, we always design and make each line according to each customer's specific requirements, so each customer can buy his own well-content line from us. | |||||

Coil-loading Car——Uncoiler——Coil-head Guide and Presser——Coil-head Straightener and Shoveler——Double-rollers Pinch feeder, Five-rollers Leveler —— Coil-head Shear——Hole Accumulator (1)——Entry Guide ——Disc Slitter —— Scrap Reeler——Hole Accumulator (2)——Pre-separator and Tensioner——Coils Pressing and Separating Bracket and Recoiler ——Coils Discharging Car layout drawing-high speed slitting line Notes:

Uncoiler, or called "decoiler", has two styles of structure: one is single mandrel style, used for coil weight not more than 20T; the other is double mandrel style, used for heavy mother coils of 25Tons or more.

Coil head shear, or called "coil head cutter", to cut off the redundant coil heads of hot rolled coils.

(1) Hole Accumulator, or called "accumulation pit/loop" two structure can be chosen: one structure is one or one pair of turnover plates whose opening and closing are driven by hydraulic cylinders, the other is lifting bridge whose up-down-moving is driven by motor. Its function is to accumulate certain amount of steel strip in the hole so as to make sure the continuous high speed working of the line.